Sustainability at Ramén Valves

For us sustainability involves everything from how we design and manufacture our products, to how we engage our suppliers and what we offer our customers. We are committed to maintaining a strong focus on quality, environmental consciousness, and the well-being of our employees in all our commitments to customers, distributors, partners, and our stakeholders.

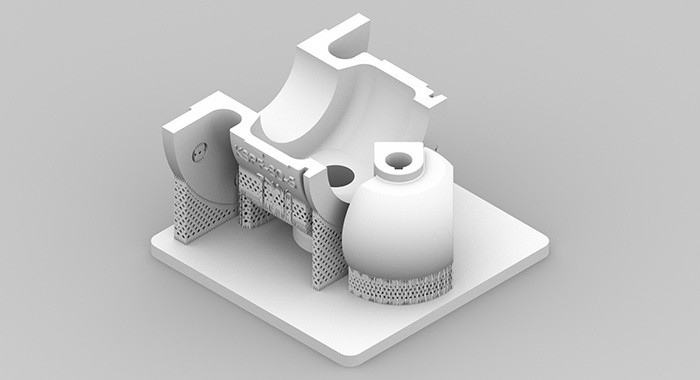

Driving sustainability with 3D control valves

We take an active role in industry development by driving innovative solutions that not only increase productivity but also have a positive impact on the environment. For example, we are proud to be one of the first valve companies in the world to offer titanium control valves produced using additive manufacturing (AM), or 3D printing. This innovative method reduces material waste, lowers energy consumption, and contributes to environmental sustainability.

Protection of resources

Our manufacturing process is certified to ISO 9001 (quality), ISO 14001 (environment), and ISO 45001 (occupational health and safety), ensuring the highest standards in every aspect of production. We continuously monitor and refine the materials and techniques we use to produce our valves, always striving for more sustainable solutions. But how do we achieve this in practice?

Sustainable energy

All valves are made with electricity from renewable sources.

Reusable Packaging

97% of our packaging materials are reusable and non-plastic.

Reduction in chemical use

Since 2015 we have reduced our use of chemicals by 25%.

Recycling

We carefully sort all production waste which our certified supplier Stena Recycling pick up and refine into new raw materials and supply to industries worldwide.

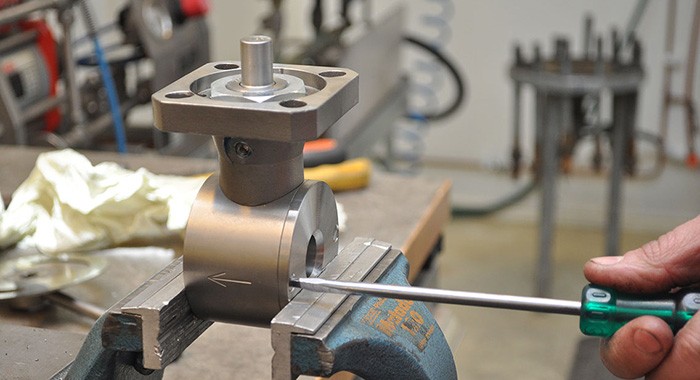

Valve service & maintenance

Our aim is to maximize the lifetime of our valves, that is why we provide service, repair, and spare parts to our customers. Through regular maintenance, you both save on costs and help save the environment. You also ensure the operation of your process. Our own Ramén valves are designed for demanding applications with reliability and easy maintenance in mind.

Environmentally friendly surface hardening

As a step in our continuous efforts to achieve a more sustainable production process, we have chosen to eliminate the use of hard chroming in our manufacturing processes. Instead, we have replaced it with the eco-friendly SuperExpanite® treatment on all our valves, a gas-based process recognized for having the lowest carbon footprint in the industry.

Sustainable transportation

A well-organized and efficient production chain is key to reducing CO₂ emissions from our transportation. By carefully planning and coordinating our processes, we can avoid urgent shipments, which not only lead to higher emissions but also create unnecessary stress and safety risks for our employees. A stable and predictable production process allows us to optimize transportation, lower our carbon footprint, and improve the work environment. In this way, we contribute to both a more sustainable transportation system and a healthier workplace.

Responsible supply chain management

We take responsibility for our entire supply chain, ensuring that our partners uphold the same high standards for quality and sustainability. To achieve this, we follow a structured approach:

- Regular supplier evaluations – Every three years, we conduct a supplier evaluation, complemented by ongoing dialogue to maintain high standards.

- Certification requirements – All suppliers must be certified according to ISO 9001 and ISO 14001 or provide equivalent documentation.

- On-site visits – Whenever possible, we conduct personal visits to strengthen collaboration and ensure compliance.

Sustainability in our daily operations

Through continuous efforts, we strive to integrate sustainability into every aspect of our operations, and we empower our employees with the knowledge and tools to make a difference.

- Thorough onboarding – Every new employee completes a training course on workplace environmental awareness.

- Clear responsibilities – Each team member is assigned at least one task aimed at reducing our environmental impact.

- Workplace safety – A dedicated safety representative ensures compliance with workplace environmental and safety standards.

Language

Language Swedish

Swedish English

English