Control valve solutions for steam

Steam is a critical component in a wide range of industries, from food processing and chemicals to pulp and paper, mining, oil and gas, and power generation. Control valves in steam applications are primarily used to manage system pressure and temperature. Given the energy-intensive nature of steam production, it’s important to choose a control valve solution that meets specific process needs, balancing cost and environmental impact. Ramén Valves offers solutions for steam and condensate control, providing customized, high-temperature valves designed to meet the rigorous demands of industrial applications.

Contact us for more information

The importance of the correct valve selection

Handling steam effectively requires careful attention to both temperature and pressure throughout the system. As steam passes through valves, it undergoes changes in these parameters, making correct valve type selection and sizing essential.

A common issue is noise, which occurs when steam reaches extremely high velocities within the valve. To minimize this, ensure the valve is accurately sized based on the correct process parameters. You can use our tool Ramén PRO Sizing for precise sizing or reach out to us for expert assistance in valve selection and sizing.

Accurate control is crucial

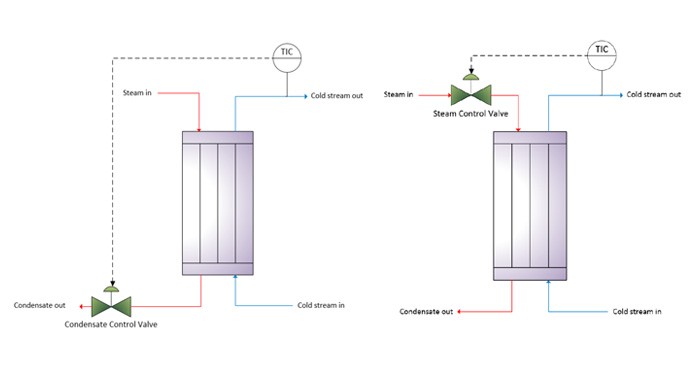

The most common method of controlling steam in heating processes is by installing the control valve on either the steam or condensate stream, as shown to the right. Accurate control is crucial for process control and thermal efficiency. When steam is used as a process stream, such as in chemical processes or distillation columns, precise steam flow control becomes even more critical for plant stability, process efficiency, and product quality.

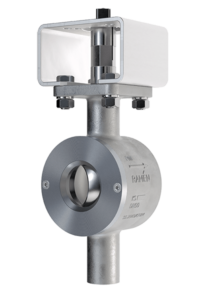

This is achieved using our Ramén KS-1B ball sector valve, ideal for high-temperature conditions.

Our solution - Ramén KS 1B ball sector valve

The modified version of Ramén KS-1B ball sector valve, is designed to withstand temperature as high as +250°C while maintaining the control precision and reliability. This is thanks to carefully selected materials and technical specifications such as:

Material specifications:

• Body: Stainless steel AISI 316L

• Ball Sector: Hard chromed

• Seat: Stellite

• O-ring: High grade EPDM-90

• Bearing: NORGLIDE® MP

Technical specifications:

• Size range: DN 25 – DN 300

• Pressure Class: PN 16 (40)

• Temperature range: up to +250°C

• Control rangeability: 300:1

• Inherent characteristic: Equal percentage

• Capacity: Kvs: 0,025 – 3840 [m3/h] / Cv:0,03-4500 [gpm]

Contact us

Language

Language Swedish

Swedish English

English