Valves that can handle the cold

Cryogenic gases are gases that exist in a liquefied state at extremely low temperatures. Due to their ability to be liquefied at high pressures and low temperatures, these gases are widely used in various industries for cryogenic applications. Their capacity to cool, freeze, expand, contract, and condense materials makes them valuable in various industrial applications. These abilities allow for a variety of processes and applications across different industries. Our valves from HEROSE are specially designed to meet the demands of these applications and ensure optimal performance and reliability. With our in-stock availability and competitive pricing, we deliver solutions that match your needs, whenever you need them.

Contact us to find out more

Short facts about cryogenic gases

- Cryogenic gases are liquefied and stored at temperatures below -150°C (-238°F).

- Argon, helium, hydrogen, nitrogen, and oxygen are the most common cryogenic industrial gases.

- Cryogenic liquefaction can reduce the volume of industrial gases by up to 600 times, making it a cost-effective solution for storage and transportation.

- Specialized equipment and materials are required to handle cryogenic gases safely due to their extreme cold temperatures and potential hazards.

- Cryogenic gases exhibit unique properties such as high density, low viscosity, and exceptional thermal conductivity at cryogenic temperatures.

Valves for cryogenic applications

One of the biggest challenges for valves used in cryogenic applications is the wide temperature and pressure variations. Because of the temperature differential between ambient and cryogenic temperatures as well as fluctuations in pressure levels, extra attention must be given to the valve sealing system. These conditions may result in leaks, which calls for extra attention to valve seats, stem seals, and body sealing.

Feel free to contact us and we will help you find the right valve for your application or book a meeting with one of our technical specialists.

We offer valve solutions for production, transport, storage and use of cryogenic gases

Processes

Various processes can generate cryogenic gases. For instance, air separation plants can produce oxygen, nitrogen, argon, and noble gases; electrolysis can produce hydrogen; and natural gas can be used to extract helium.

Storage

Cryogenically liquefied industrial gases can be stored in stationary containers for extended periods without significant evaporation.

Transport

To transport cryogenic gases from the production site to the user, they can either be conveyed through pipelines or transported in cryogenically liquefied form by truck, using specific vacuum-insulated containers or tanks.

Recommended valves for cryogenic gases

Ramén Valves offers a variety of valves from HEROSE that are suitable for cryogenic applications due to their ability to withstand extremely low temperatures without compromising performance. These valves maintain their integrity even at cryogenic temperatures, minimizing the risk of leaks.

Explore our range of valves through our product platform by clicking on the links below. In the product platform you will find detailed pricing and delivery information. If you need help selecting the appropriate valve for your process, feel free to contact our technical specialists via our live chat for immediate assistance.

HEROSE globe valve 01741. Stainless-steel globe valve, approved for air vapours, gases and cryogenic liquefied gases

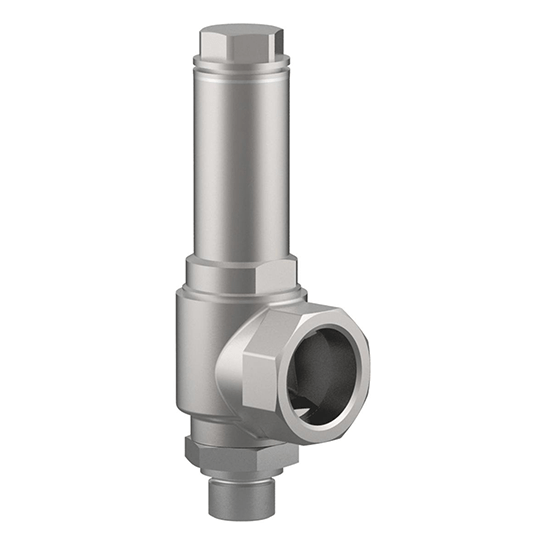

HEROSE safety valve model 06383. Safety valve for protection of pressurized devices. Cleaned for oxygen applications and suitable for cryogenic applications.

HEROSE globe valve FullX 11C01. Commonly used at air separation plants and coldbox systems.

Contact us

Use the form to contact us.