A checklist for ordering the right valves

Ensure you’re ordering the correct valves for your enrichment plant with this comprehensive checklist.

In the mining industry, the applications are often demanding, with valves operating in some of the harshest environments. Therefore, the equipment must be robust and resilient, particularly when handling highly abrasive and erosive slurries. These challenging conditions put significant demands on valves, making it crucial to choose the right valve solution to minimize maintenance costs and ensure reliable performance. With over 70 years of engineering expertise, we understand the unique challenges of mining and offer tailored control valve solutions designed to meet these tough demands with precision and durability.

To meet the needs of the mining industry, we developed the Ramén KSG Ball Sector Valve, a specialized, rubber-lined version of our Ramén KS model. The KSG’s durable rubber lining provides exceptional resistance to wear and tear, making it ideal for handling abrasive materials such as slurries, gravel, and iron ore. All wetted parts are lined with polyurethane (PUR) and natural rubber making particles bounce off rather than wearing of metal material on the wetted parts. With its superior resilience, precise control, and cost-effective operation, the KSG stands out as a unique solution in the market.

Our valves are designed to handle a wide range of applications in mining, including processing different types of ore such as iron ore, zinc ore, and gold ore. Typical applications are:

Pinch valves are often used in the mining industry, but over the years, we have replaced many with our Ramén KSG Ball Sector Valve. Here's why:

The KSG Ball Sector Valve offers precise flow control with 8 different reduced port options, making it ideal for low flow rates where pinch valves struggle, especially in smaller DN25 sizes.

KSG valves provide smooth control across the full stroke, unlike pinch valves which are effective only between 20%-80% of their range.

The round bore of KSG valves reduces wear compared to pinch valves, making them ideal for abrasive conditions.

KSG valves have a slim, lightweight design, needing less torque and allowing the use of smaller, more affordable actuators. Pinch valves, on the other hand, are bulkier and often require custom actuators, increasing both cost and complexity.

Abrasion can be costly. The Ramén KSG Ball Sector Valve minimizes wear and tear, extending the service life even in the harshest mining environments. This is how: Ramén KSG Ball Sector Valve is self drained, has no hidden cavities and causes no dewatering. This ensures that no clogging occurs, resulting in a lifespan more than ten times longer than other comparable valve technologies. Even when wear eventually occurs, the Ramén KSG valve is self-adjusting, automatically adapting its position to maintain consistent flow characteristics, ensuring reliable and efficient performance over time.

In mining, every minute of downtime costs money. That is why it’s important to choose valves that offer a long service life and are easy to replace and maintain. The Ramén KSG Ball Sector Valves are designed with reliability and ease of maintenance in mind. They require only simple seat and O-ring replacements for maintenance. This clever design not only helps keep maintenance costs low but also contributes to environmental sustainability. We always recommend stocking a spare parts kit already when purchasing the valve, for future spare part replacements.

Here are some common applications in the mining industry and why our Ramén KSG ball sector valve is the ideal choice for these applications.

Application:

Throttling thickener deposits

In this case the KSG valve proved that soft natural rubber is much more resistant to wear than steel. In this iron mine, the KSG valve showed no wear after months of continuous use, outlasting other valve types such as rubber pinch valves and lined butterfly valves. This leads to lower maintenance costs and reduced downtime.

Application:

Magnetic separator water control

The KSG valve proved to be highly durable in this demanding iron mine, remaining in very good condition after two years of use. Its superior performance in severe conditions led to it replacing other valve types, like pinch valves, as the preferred choice for reliability and reduced maintenance.

Application: Outlet throttling from rubber-lined centrifugal pumps

In this application the steel tube in the outlet from the valve was worn out and replaced with a rubber lined tube. This highlights the rubber lining’s ability to resist wear and extend the lifespan of the valve in harsh conditions, making it a much better choice for long-term reliability.

Here are some common mining applications where our valves have demonstrated proven success.

Application:

Control of lime

This case explores a successful transition from traditional pinch valves to the more robust Ramén KS Ball Sector Valve in a demanding application, leading to improved durability and performance.

In any industrial process, the right valve sizing is crucial for achieving optimal performance. A properly sized valve solution ensures cost-effectiveness, reliability, and sustainability. Our Ramén PRO Sizing tool simplifies the process, ensuring your valve is perfectly matched to your specific media, flow rates, and and operational conditions of your plant. Combined with our engineering expertise, the Ramén PRO Sizing tool makes sure the best possible solution is offered for your needs, saving you both time and money.

Watch our instructional video to learn more about Ramén PRO Sizing.

Check out our in-depth articles on valves for enrichment plants, to help you make informed decisions about valve selection and maintenance.

Article

Ensure you’re ordering the correct valves for your enrichment plant with this comprehensive checklist.

Article

Develop a proactive maintenance plan to minimize costs and prevent accidents.

Article

Learn how proper valve selection and maintenance can make your mining site safer.

In addition to the Ramén KSG Ball Sector Valve we offer a wide range of specialized valves to meet the unique needs of the mining industry. These valves are used worldwide, from copper mines in Peru to iron ore mines in Sweden and are engineered to withstand the toughest conditions.

Ramén KS Ball Sector valve with hand lever

Suitable for abrasive media and harsh conditions. Provided with a lockable handlever.

Ramén KSC pneumatic Ball sector valve

The Ramén KSC control valve offers the highest performance for controlling and isolating gases and fluids.

Ramén KSC electrical Ball sector valve

The Ramén KSC control valve offers the highest performance for controlling and isolating gases and fluids.

Badger Meter RCV micro control valves

These valves ensure precise flow control in demanding environments. Its rugged construction guarantees durability, even in the harshest conditions.

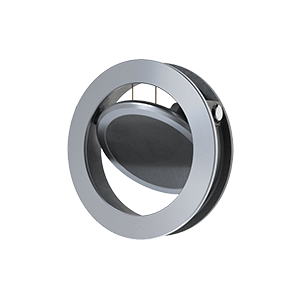

A safety device designed to prevent the creation of a vacuum or negative pressure within a closed system or container.

Used to protect, for example, compressors and pumps from damage that can be caused by backflows.